|

Products for the Battery Industry:

Products for the Battery Industry:

-

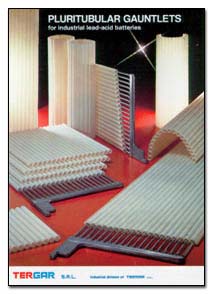

PLURITUBULAR GAUNTLETS -

PLURITUBULAR GAUNTLETS

The aim of the world’s leading industrial battery

manufacturers is the construction of a product with considerably

increased performance and with a longer trouble-free life

in  the

most extreme conditions ranging from arctic to tropical. the

most extreme conditions ranging from arctic to tropical.

Research and Development teams are well aware one of the

secrets of high performance traction batteries is tubular

plates made with reliable materials and high quality

gauntlets.

Throughout the past years, TERGAR have pioneered many fundamental changes

in multitubular gauntlet technology and has supplied the

Battery Industry with many million of woven gauntlets, which

proved to meet the most stringent quality requirements.

TERGAR's team has been known as one of the leaders

in the tubular gauntlets Industry for the quality product

we manufacture and the service we provide. A modern production

facility, designed and developed by TERGAR, manufactures

gauntlets to the most exacting of customers’ quality

and reliability specifications; we are now in a position

to offer a complete range of gauntlets, depending

on customer’s needs: engineered woven and non-woven

gauntlets

ENGINEERED WOVEN GAUNTLETS

HD-1416 woven gauntlets with engineered fabric structure

offer higher resistance to chemical oxidation, better energy

utilisation due to enhanced elastic compression of the active

material, and longer trouble-free battery life. It is therefore

specially recommended for Heavy Duty applications

where the reduced internal resistance and the strong fabric

structure results in improved performance with higher capacity.

HD-1416 engineered woven gauntlets main characteristics

are:

- Easy filling with paste or powder thanks to the peculiar

hardness of the tube

- Strong and elastic structure and no lack of stability

even in heavy duty application and in high temperature

- High porosity

- Low electrical resistance even with a close fabric structure

- High mechanical strength (over 40 N/cm in both directions)and

controlled elasticity

- Very high resistance to the oxidation

More

exhaustive information about woven gauntlets is available

in the article G. Terzaghi "Engineered woven gauntlets

to improve the performance of tubular plates"

Journal of Power Sources 73 (1998)78-85

ENGINEERED WOVEN GAUNTLETS

DATA SHEET

| 1.

Characteristics |

1.

Verzeichnis |

1.

Caracteristicas |

|

| 1.1 Woven pluritubular

gauntlet, type "HD", 75% high tenacity polyester,

high torsion, continuos filament yarns with protective

resin coating. |

1.1 Halbsteife

Röhrchentasche Type "HD" gewebt aus 75%

Hochfestes Polyester Multifilamentgarn |

1.1 Funda multi-tubular

semirigida tipo "HD" obtenida mediante tela

tejida con el 75% de hilo continuo de poliéster

de alta tenacidad, torcido y resinado |

|

| 1.2 Color: natural

white |

1.2 Farbe: naturweiss |

1.2 Color: blanco

natural |

|

| 1.3 Resin coating:

the gauntlet is impregnated with 19% (TERGAR formulation)

synthetic resin |

1.3 Harzdeckung:

die Tasche wird von TERGAR mit mindestens 19% imprägniert |

1.3 Impregnación

de resina: la funda se impregna con un 19% minimo de

resina sintética (formula de TERGAR) |

|

| 1.4 Fabric

structure: the composition of the tube wall is:

yarns per cm. (Crosswise)

yarns per cm. (Lengthwise) |

1.4 Das Gewebe

der Röhrchen Wand hat folgende Zusammensetzung:

Fadenzahl pro cm. (Querrichtung) - Kette

Fadenzahl pro cm (Längsrichtung)-Schuss |

1.4 Estructura:

la composiciòn de la pared del tubo es:

número de hilos por cm (trasversal)

número de hilos por cm (longitudinal) |

14,0

17,5

|

| 1.5 Wall thickness

of the tube |

1.5 Wanddicke |

1.5 Espesor

de la pared de tubo |

0,3 mm |

| 1.6 Weight per

linear meter of tube |

1.6 Gewicht

pro Linearmeter Röhrchen |

1.6 Peso por

metro linear de tubo |

6,2 g |

| 1.7 Weight per

square meter of standard gauntlet |

1.7 Gewicht

pro Quadratmeter Röhrchen |

1.7 Peso por

metro cuadrado de funda |

630 g |

| |

|

|

|

| 2.

Standard Sizes |

2

Abmessungen |

2

Dimensiones |

|

| 2.1 Standard

internal diameters.

Other diameters or shapes are available on request |

2.1 Standard

Innendurchmesser.

Verschiedene Formen und Durchmesser auf Wunsch |

2.1

Diámetros internos estándard.

Otras dimensiónes son disponibles à

pedido |

8,0 - 8,2

mm

8,4 - 8,7 mm

|

| 2.2 Number

of tubes: to Customer specification |

2.2 Röhrchenanzahl:

beliebig |

2.2 Número

de tubos: à pedino |

|

| 2.3 Tube

pitch, referred to standard diameters |

2.3 Abstand

zwischen den Röhrchen, auf Standarddurchmesser

bezogen |

2.3 Paso

entre tubos con referencia a los diámetros estándard |

9,7 mm |

| 2.4 Maximum

gauntlet length |

2.4 Maximalhöhe

der Tasche |

2.4 Altura

máxima de la funda |

2.200mm |

| 2.5

Lateral finishes:

simple cut

side protection |

2.5

Seitenabschluss:

simple cut

side protection |

2.5

Acabados laterales:

contado simple

protección lateral |

C or T

DSP or SP-T |

| |

|

|

|

| 3

Chemical and Physical Data |

3

Physikalische und Chemische Angaben |

3

Características Químico - Físicas |

|

| 3.1 Bursting

strength of the tube |

3.1 Berstfestigkeit |

3.1 Resistencia

a la rotura por sobrepresión |

> 30 bars |

| 3.2 Increase

of outside diameter of the tube at 8 bar of internal

pressure |

3.2 Zunhame

des Aussendurchmessers des Röhrchen |

3.2 Aumento

del diámetro ext. del tubo sometido a una presión

int. de 8 bar |

< 2% |

| 3.3 Mechanical

stress cycling test: number of cycles |

3.3 Ermüdungstest:

Zyklen |

3.3 Ensayo

de fatiga: número de ciclos que deben superar |

>200.000 |

| 3.4 Electrical

resistance of the wall tube |

3.4 Elektrischer

Widerstand |

3.4 Resistencia

eléctrica |

0,35 Ω

cm² |

| 3.5 Chlorine

and derivates: absent |

3.5 Chlor

und Derivate: Abwesend |

3.5 Cloro:

exento |

|

| 3.6

Tensile strength

Crosswise (one cm of gauntlet)

Lengthwise(one cm of tube wall) |

3.6

Zugfestigkeit

Querrichtung (ein cm von Tasche)

Langsrichtung(Streife von Röhrswand) |

3.6

Resistencia la tracción

transversal (por cm de funda)

longitudinal(banda de 1 cm de pared) |

60 daN

40 daN

|

| 3.7 "Reflux

Test", hours |

3.7 Rückflusstest,

Stunden |

3.7 "Reflux

Test", horas |

47 ± 2 |

| 3.8 Battery

test. Life - time in charge and discharge cycling test

(DIN 43539), cycles |

3.8 Batterietest.

Leben-sdauern in Lade Entladezyklen Test (DIN 43539),

Zyklen |

3.8 Ensayo

en batería. Ciclos de carga y descarga (DIN 43539),

ciclos |

> 1.800 |

| |

|

|

|

| 4

Tolerances |

4

Zulaessige Toleranzen |

4

Tolerancias |

|

| 4.1 Tube

diameter |

4.1 Innendurchmesser |

4.1 Diámetro

del tubo |

-0 +0,15

mm |

| 4.2 Gauntlet

height |

4.2 Länge

der Taschen |

4.2 Altura

de la funda |

± 0,5 mm |

| 4.3

Gauntlet width |

4.3

Breite der Taschen |

4.3

Anchura de la funda |

± 1% |

| 4.4 Tubes'

pitch |

4.4 Abstand

zwischen den Röhrchen |

4.4 Paso

entre tubos |

± 1% |

| 4.5 Electrical

resistance |

4.5 Elektrischer

Widerstand |

4.5 Resistencia

eléctrica |

± 0,05 Ω

cm² |

NON-WOVEN GAUNTLETS

NW150 non-woven gauntlets have been developed to

provide the market with a cheaper product.

NW150 non-woven gauntlets main characteristics are:

- good active material retention

- very low shedding

- fine pore structure

- specially suitable for all wet filling methods (slurry

and paste)

Improved technology and our patented production process

grant our gauntlets the reliability and consistent performance

you expect from an experienced leading supplier, and enable

us to offer a premium quality product at a very competitive

price.

We will be glad to receive your inquiries (please use the

FEED

BACK FORM in this web site) on specific sizes and

diameters currently used at your plant; we will be than

able to submit also our best offer with a free of charge

sample shipment to be made in accordance with your specific

requirements

NON-WOVEN GAUNTLETS

DATA SHEET

| 1.

Characteristics |

1.

Verzeichnis |

1.

Caracteristicas |

|

| 1.1

Material: 2 layers of point-sealed non-woven fabric

binded by stitch. Natural unbleached fabric composed

by polyester fibers, treated with protective synthetic

resin, sewed with polyester sewing thread |

1.1

Material: 2 Lagen eines punktförmig verdichtetes

Vliesmaterials mittels Nähten verbunden. Unbehandeltes,

nicht gebleichtes Stoff hergestellt aus Polyesterfasern,

mit einem schützenden, synthetischen Harz versehen

und mit einem Polyesterfaden vernäht |

1.1

Material: 2 capas de tejido unidas por costuras.Tejido

de color natural compuesto de fibra de poliéster,

tratado con resina sintética protectora, cosido

con hilo de poliéster. |

|

| 1.2 Color: natural

white |

1.2 Farbe: naturweiss |

1.2 Color: blanco

natural |

|

| 1.3

Resin content: |

1.3

Harzdeckung: |

1.3

Impregnación de resina |

18

± 1% |

| 1.4 Wall thickness

of the tube |

1.4 Wanddicke |

1.4 Espesor de la

pared de tubo |

0,6 mm |

| 1.5

Weight per linear meter of tube |

1.5

Gewicht pro Linearmeter Röhrchen |

1.5

Peso por metro linear de tubo |

4,9

g |

| 1.6 Weight per square

meter of standard gauntlet |

1.6 Gewicht pro Quadratmeter

Röhrchen |

1.6 Peso por metro

cuadrado de funda |

500 g |

| |

|

|

|

| 2

Standard Sizes |

2

Abmessungen |

2

Dimensiones |

|

| 2.1

Standard internal diameters |

2.1

Standard Innendurchmesser |

2.1

Diámetros internos estándard |

8,0-8,2-8,4

mm |

| 2.2 Number of tubes

per gauntlet |

2.2 Röhrchenanzahl |

2.2 Número

de tubos de la funda |

19 |

| 2.3

Tube pitch for standard diameters |

2.3

Abstand zwischen den Röhrschen |

2.3

Paso entre tubos con referencia à los diámetros

estándard |

9,6

or 9,7 mm |

| 2.4 Maximum gauntet

length |

2.4 Maximalhöhe

der Tasche |

2.4 Altura máxima

de la funda |

600 mm |

| |

|

|

|

| 3

Tolerances |

3

Zulaessige Toleranzen |

3

Tolerancias |

|

| 3.1

Tube diameter |

3.1

Innendurchmesser |

3.1

Diámetro del tubo |

-0

+0,15 mm |

| 3.2 Gauntlet length |

3.2 Länge der

Taschen |

3.2 Altura de la

funda |

± 1,0 mm |

| 3.3

Gauntlet width |

3.3

Breite der Taschen |

3.3

Anchura de la funda |

±

1,5% |

| 3.4 Tubes' pitch |

3.4 Abstand zwischen

den Röhrschen |

3.4 Paso entre tubos |

± 1,5% |

| 3.5

Electrical resistance |

3.5

Elektrischer Widerstand |

3.5

Resistencia eléctrica |

0,30

Ω cm² ± 0,05 |

The above data are given for information only.

[ Back

to previous page ]

[ products | company profile | contact

us | disclaimer | site

map ] |